Pragma Case Study: Building a Business from scratch with a payback of 167 days

My goal with the Pragma project was to innovate a traditional industry by introducing modern product design and lean methodologies, creating a durable and theft-resistant cemetery plate, which led to a profitable business with a payback period of just 167 days.

Abstract

This case study explores the creation of Pragma, a business transforming the traditional cemetery lettering industry with modern Product Design and Lean methodologies. By selecting durable aluminum composite panels (ACM) and UV printing, we developed theft-resistant, weatherproof cemetery plates. Prototyping and validation through customer feedback and B2B outreach confirmed market demand.

With streamlined production and effective Google Ads marketing, the business expanded across southern and southeastern Brazil, continuously optimizing products based on customer preferences. This experience emphasized the value of integrating design with business strategy, significantly enhancing my skills as a product designer.

Background

My father used to make cemetery lettering and plates in metal in a very traditional and manual way. It was a medieval process consisting of hand-carving the letters into wood and then casting them in metal. The process was extremely time-consuming and labor-intensive, after the letters came from the foundry they still required extensive hand-finishing, polishing, painting and varnishing.

In the last decades there was an increase in robberies at the cemetery for scrap metal that people didn't want to purchase traditional metal plates anymore. Seeing the potential for improvement and innovation, I decided to introduce modern technology and design principles into this industry. My sister was sick and unemployed at the time, so I saw this as an opportunity not only to create a successful business but also provide her with a meaningful job.

Research

The main question of this new product we were developing was: Material. What material should we use to create a durable aesthetically pleasing cemetery plate that would mimic metal and would deter theft? Another aspect of the material was to be easy to cut into shape preferably with a type of CNC machine, this way we could eliminate the manual carving process and increase efficiency.

We considered a thin plate of stainless steel, acrylic, expanded PVC, aluminum composite panels, and various types of plastics. After extensive testing and research, we decided to test aluminum composite panels (ACM). The central reason for choosing aluminum composite panels was that there is a huge range of finishing options available, and some of them resemble the appearance of metal. Working with ACM presents a major challenge as its composition of multiple materials makes it unsuitable for cutting with laser cutters. Laser cutters would've been our first option for manufacturing as it can cut with very high resolution and precision. Our lettering was very tiny with very intrinsic details and required a high level of precision in cutting. To overcome this challenge, we decided to utilize CNC routing machines instead of laser cutters.

For the cemetery plates, we started the research with the printing technologies available, such as digital printing, UV printing, and screen printing. The most critical factor for us was achieving durability and resistance to weathering, as these cemetery plates would be exposed to various outdoor conditions. After talking to many specialists in the printing industry we opted for the UV printing process, as it offers superior resistance to UV rays and weathering compared to other printing methods. It could also print on the surface of ACM panels, that could potentially stream our production process and reduce the need for additional materials as we were already using ACM for the letterings.

Prototyping

In order to test the lettering we designed a simple name by hand, digitalized and sent out to a CNC service to try to cut the ACM into the desired design to check if the quality was good enough. We managed to buy a small sheet of ACM just for the purpose of the test. The whole cost of this attempt was around R$25, while producing in metal would cost about R$110 of material plus 4/5 hours of intense heavy labor.

The result was great, the machine managed to cut most of the intricate details and the price of material plus cutting service was way within our budget. There were some small details the CNC didn't reach with absolute precision but we could overcome those by adapting the font. The lettering prototype was a success, now was time to test the plates and the printing.

For the plate we used the same material as the lettering. We cut a plate in the same size as the traditional designs but this time we added a picture on top of it to be printed together with the plate. Back in the day that would have to be done separately printed on porcelain and done by a third party provider. We sent the plate and the designs to the printer and the next day the plate was ready. The cost of the print was R$5 and the material was around R$30, while producing in metal and porcelain would have cost us around R$150 plus 4/5 hours of labour. The print provider gave us 5 years warranty on the UV print. In order to test the durability of the print we placed the plate outside for several months, exposing it to various weather conditions including sunlight, rain, and extreme temperatures. The UV print on the ACM plate proved to be highly durable and resistant to weathering, maintaining its quality and appearance even after months of exposure to harsh.

Validating

In order to validate the market pull of the the product we took two different approaches:

1- We've created fake ads that lead to a landing page with a message explaining the product was still in development and for the customers to leave their email if they were interested in the product. This is a Lean strategy that has the only purpose of evaluating if people would be interested in this kind of product.

2- We reached out cemetery builders whom resell cemetery signage, showed the final product and ask them to try to sell and gather feedback about the product.

For the first strategy we set a budget of R$10 per day to run the ads on Google Ads for a week. Quickly the budged ran out and google instantly recommended to increase the budget in order to achieve maximum reach. We screwed up the landing page and due to code errors we couldn't gather any email address. However, despite the technical issues with the landing page, we received an overwhelming response from potential customers who were interested in our product.

For the B2B approach we received a lot of questions about the durability of the product. They were skeptical about the material, although they were very keen on the fact that the product didn't have any scrap value. They were really concerned with the amount of robberies and final consumers didn't want to replace their robbed signs with metal products anymore. We gave them samples of the 2 types of products plus some pieces of the raw material to hard test. They came back to us and showed interest and wanted to know more about pricing.

Product validated!

Production

After validating the market demand for our products, we needed to find the best way to produce. Sending the material to be cut externally would complicate production and put responsibility in some one else’s hand. Brand new CNC routers were around the R$100ks and most of them had many more features than we needed. We wanted to have small investment as possible, so we started to look for second hand alternatives. The same person who cut the first prototype indicated us some one that had bought the machine but was not really using it. We managed to buy the machine for only R$13K.

As for the UV printer it was a much higher price, they would start at the R$300K. We made a deal with a local printer and he compromised to charge us R$5 per print so it was still relatively cheap. We didn't want to spend too much cash upfront so we took a Lean approach and decided to outsource the UV printing.

For the material, as ACM is a widely used product in the construction industry, it wasn't hard to find plenty of providers and within 6 months our material cost reduced by 50%.

We placed the CNC router at our garage, bought a cheap computer, a small bike to transport products around the printer and post and our production workflow was complete.

Font Design

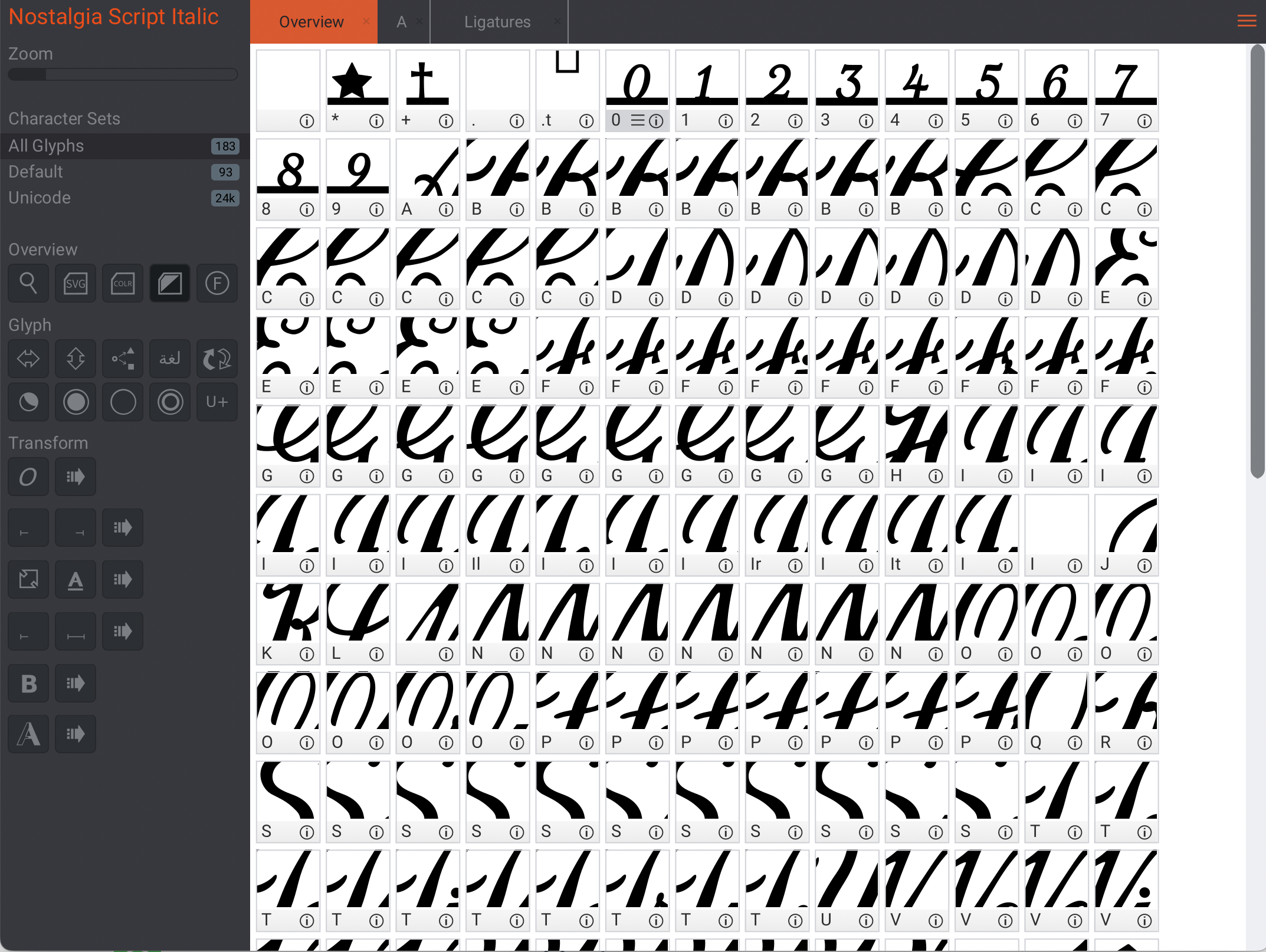

For the font, we wanted to make a font similar to what my father did for the last 30 years. He started with a manuscript font base and adapted for the forgery manufacturing process. My father has been optimizing the font for years and my task was only to digitalize and turn into to a usable font file. But that turned out to be more difficult than I thought.

Most of font design tools are super expensive or too complex for a beginner like me. After testing with some free trials and watching hours of youtube videos (at 1.5x) I managed to create a decent font using a cheap but simple software called BirdFont.

Creating the font was relatively simple, but making a manuscript font to work is another story. Each and every pair of letters needed to be manually spaced, kerned and hinted. Plus the Capital letters with it's designed pair.

Also each letter needed a tail and a head to smoothly connect to the next font and also do not look terrible when the letter was at the end of the word. To solve this I created a “connector" that worked similar to a tile pattern, where the last letter would automatically blend with the next one. This whole process took me 4 weeks to finish, but then we had a unique font that no other competitor had in the market. Also a customer could have a previous name made in metal at the cemetery and using our product meant he could match the same design as the previous names.

Marketing and Pricing

As for price strategy, we focused on positioning our product as a high-quality and innovative solution, highlighting its durability, resistance to weathering and anti-teft features, so we set the price only 10% cheaper than the traditional metal solution. We didn't want to necessarily match other types of solution's price, of course we checked competitors pricing but price wasn't going to be the deal breaker. Still our markup was roughly 200% over the production cost. This way we had a highly profitable product with added value, still cheaper than traditional solutions. For the B2B we decided to offer 30% discount over the retail price for bulk orders, incentivizing cemetery builders to purchase in larger quantities.

We didn't want to restrict our sales to our own region, so we started to look for online e-commerce platforms that would allow us to reach a wider customer base. That would also help us to process PIX (Brazilian P2P national payment system), credit cards, debit card and invoice payments and provide an easy to maintain CMS platform as we couldn't afford to develop this whole solution from scratch. For this solution we considered, Shopify, Nuvemshop, Loja Integrada and Tray. Nuvemshop gave us a free period to try, it was cheaper than the others and had plenty of tutorials online. So we decided to go with them.

We integrated our e-commerce to all the APIs possible in order to test payed advertising and understand which ones had better leads. Most of the traffic to our website came from Meta and Google ads. So we assigned the same budget to both platforms and monitored the messages and sales generated from each one. It turned out that Meta had cheaper leads, but they were from extremely poor quality, there was a lot work to be done over Whatsapp to answer all the questions and conversions were low. While with Google ads, customers were more qualified and the conversion rate was much higher. Also our products were displayed in Google Shopping and being able to advertise there, gave us good results in sales. As for today 90% of our marketing budget goes to Google ads, and 10% to Meta.

Product Design Optimization

After designing the website, integrating with payments processor, and all the APIs, we felt the need to increase our range of designs. We analyzed our most popular products, did a market research and created new designs based on customer preferences. We also added double the amount of finishings, giving our customers plenty of options to chose from. Recently we have also added house numbers to our product range which falls out cemetery line but that is a way try to penetrate other markets.

Results after 2 years

Our initial investment was around R$27K and from day one, we saw steady growth in our sales. Mostly from the online platform. After only 167 days we managed to recover all the initial investment and start making a profit. This success can be attributed to various factors. The decision to keep the business as Lean as possible allowed us to try and change strategies quickly and test straight away. Even though we are still making improvements, it was relatively quick to understand which strategies worked best.

Today we have consolidated sales and have expanded across the south and south-east regions. Our conversion funnel on the website went from 4% to 34%. The price per conversion went from R$170 to R$40.

I believe the business has reached our peak and we have maximized our potential in terms of growth and profitability, at least covering these regions. In order to expand further we may need to open another branch somewhere more north of Brazil in order to reduce cost and time of delivery. We tried to advertise in other parts of Brazil, but when the shipping cost and time increase, conversions go down.

What I've learned

In my previous jobs, I have mainly focused on the design and user experience, I couldn't see the big picture and always fought to have the best design no matter what. I learned the importance of targeted advertising and utilizing the right platforms to reach our desired customers. Design is not the only important thing to give users the best experience and in order to make a business thrive it's needed to focus on so many other things. I had to make a lot design sacrifices in order to keep the project as simple and versatile as possible, like designing a landing page that was not as pretty as I would, but keeping simple to update and optimizable for conversions as possible. The business logo was made to match the website template in which was built and not the other way around. Back in the day I would never take these decisions, but made so much sense when I was developing the whole project.

I believe I became a much better designer after this experience. It's really important to understand the whole business in order to design successful products, which might not be the best design decision alone, if you look only from that perspective. I learned how easy is to learn new skills once you put hands on, specially if you are paying for a service. Once I started advertising with Google and Meta I get free weekly consultations to optimize my ads. It was so much better to have all these works done by me, having control, instead o f hiring an external agency.

In conclusion, it was great to apply Product Design principles to a new business but it was immensely greater to live the journey and learn from every challenge along the way. Starting a business from scratch has been one of the most rewarding experiences of my life and have helped me become a better product designer.